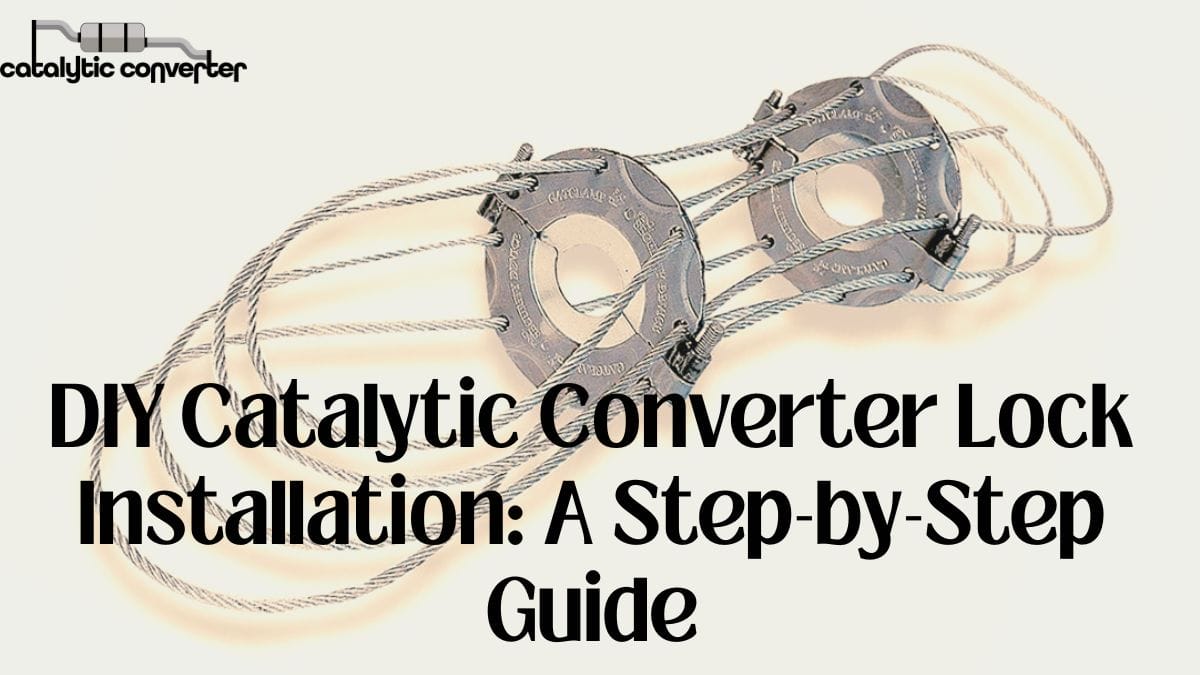

DIY Catalytic Converter Lock Installation: With rhodium prices rising, more and more catalytic converters are being stolen. Vehicle owners are desperate for solutions. Professional installation of protective locks offers maximum security, but high costs and wait times may discourage drivers. Fortunately, resourceful owners can DIY catalytic converter lock installation themselves in their garages. Just use common sense, basic mechanical skills, and the proper tools.

This exhaustive guide covers everything required to DIY catalytic converter lock securely.

- We provide a list of necessary and additional tools.

- Explain the best way to install it.

- We give step-by-step checklists.

- Offers solutions for common problems.

- Estimate how long it will take.

Our goal is fully empowering motivated owners to take the bull by the horns, thwarting opportunistic platinum banditry. Let’s get our hands dirty!

Please read our guide on choosing the best catalytic converter lock for your car.

Optimal DIY Catalytic Converter Lock Toolkit

Any veteran mechanic will confirm a quality toolbox proves truly essential for smooth installations. Arm yourself with these essentials:

Core Hand Tools

- Common SAE & metric socket sets with short and long extension bars fitting converter lock kit bolt/nut fasteners. Loose or improperly sized sockets risk rounding off edges on hardware.

- This 3/8″ ratchet wrench can be used to tighten things with different levels of force. It helps avoid tightening too much and risking damage to the protected areas.

- Set of mixed standard and Phillips screw bit drivers matching provided fastening hardware.

Support Equipment

- Sturdy steel jacks are certified to support vehicle curb weight safely, enabling secure underside access without risky improvised supports prone to collapse.

- Hydraulic floor jack/trolley jack for initial vehicular lifting before jack stand transfers.

- Powerful LED work lights with magnetic mounts provide ample underbody illumination in dimly lit garages, facilitating efficient inspection and repairs.

Model-Specific Lock Hardware Kits

- Buy universal converter lock sets with plates, sensors, wiring, and instructions for different vehicles. Or, get custom kits.

Basic Work Safety Equipment

- Durable mechanic gloves with reinforced knuckle protection shield your hands from abrasions, contusions, and impact injuries.

- Anti-glare safety goggles guard eyes against errant debris when working around hot exhaust components.

- Knee pads provide insulation against cold concrete.

Specialty Catalyst Tools

- Use a penetrating lubricant spray to loosen stubborn bolts or gaskets under your vehicle. This spray helps loosen them by breaking down the grime and corrosion that builds up over time. This saves rounded edges/stripping.

- Threadlock adhesive is essential for sustaining consistent tension across fasteners, preventing any risky spontaneous loosening over months from vibration or thermal cycling.

- We can use high-temperature exhaust manifold spray paint to touch up and restore worn finishes on exhaust manifolds. It’s durable and resistant to heat, which is especially helpful after making modifications.

Taking time to compile a purpose-built converter lock toolkit makes installations far smoother for both vehicles and their owners. Now, let’s ensure preparations are prime protections for success.

Please read our guide on diagnosing and fixing catalytic converter lock problems.

Critical Preflight Precautions for Smooth DIY Catalytic Converter Lock Installation

Meticulous planning prevents painful problems down the road! Before picking up tools, always confirm the following:

Target Vehicle Compatibility

- Verify that the purchased catalytic converter lock model expressly matches your vehicle by chassis make, model, year, and trim specifications. Many universal kits fit multiple configurations, but component variations can exist across different packages. Your exhaust layout must align with the lock anchoring approach.

Installation Sequence Review

- Carefully study all provided instructions, diagrams, and digital media resources accompanying lock hardware kits. Review the entire process first for hidden steps that are easy to miss without explicit callouts. Identify any gaps requiring online secondary guidance per application complexity.

Baseline Inspection

- Initially, examine the factory exhaust assembly fitment by looking for preexisting damage like vibration-induced cracking that risks worsening when adding stiffer guards. Especially scrutinize hangers and joints with play for necessary proactive reinforcements. If unaddressed, you want to avoid new shields breaking what still functions well.

Covering preflight bases thoroughly prevents painful gut punches down the road. Now let’s enter step-by-step installation procedures:

Step-By-Step Instructions for DIY Catalytic Converter Lock Installation

With preparations, we’re ready to secure DIY catalytic converter locks:

Parts Layout

- Unbox all provided converter shield components and hardware, matching their locations against the instruction diagram. Keep organized groupings close by for each successive installation sequence to avoid wasting time rummaging later.

Initial Positioning

- Loosely affix the lock framework into its final desired straight geometry, conforming to surrounding contours without fully torquing. Gradually sneak up the perfect snugness through patient precision alignments.

Torque Hardware Methodically

- To prevent uneven distortion stresses, use diagonal sequence stage-tightening. This keeps clamping pressures uniform across mounting surfaces. Instead of securing one side first, do both sides simultaneously. Alternate all around several passes.

Confirm Converter Coverage Protection

- Verify catalytic converter bodies sit fully encapsulated within protective cages with sufficient physical coverage on all exposed surrounding sides. Remove them to prevent thieves from exploiting security gaps and endangering installations.

While ensuring universal hardware fits varying factory configurations demands artistry, mastering mounting logistics from the initial steps prevents problems. But mistakes occasionally happen. Let’s troubleshoot workarounds.

Field Fixes for Common DIY Converter Lock Install Challenges

In a non-ideal world, unanticipated challenges can arise:

Visual Interference Alignment Obstructions

If nearby exhaust components block full shield plate coverage in initial locations, redrill alternate anchor attachment holes rerouting around obstacles after holistically analyzing all underbody layouts. Improvise intelligently within reason before abandoning efforts!

Rusted Fastener Wear Risks

If you have bolts or brackets with stuck nuts that won’t move, try drilling them out. Then, replace them with new hardware that is strong and won’t break. This will fix the problem and make it safe again. Don’t just cover over deficiencies, risking future failure when adding additional weight. Handle with care to avoid fractures.

Universal Fit Gaps

Double-check that kit model numbers precisely match your vehicle parts catalog down to the trim and package levels, identifying any hardware mismatches. Wrong parts risk poor mounting alignments, creating vulnerability gaps. Criminals are aware of bringing tools fully prepared to exploit everything except time delays. Seek custom one-off fabrication shops offering enhanced security.

Patience, care, and understanding of engineering adaptation principles prevent most complications. But even veterans know that seeking professional assistance makes sense, especially when trying installations for long-term protection confidence. Let’s talk timing.

Projected DIY Catalytic Converter Lock Installation Duration

Expect 1-5 hours for typical exhaustive do-it-yourself exhaust lock retrofits:

- The most straightforward clamp adapters can be installed within 60 to 90 minutes.

- Custom drilling, welding, alarm wiring, and hardware modifications can run hours with the most complex layered sensor integrations, possibly spanning days depending on parts shipments.

Staged efforts in manageable chunks help digest inevitable frustrations over weeks. Spending equal time planning appropriate scope matching technical skill levels proves essential upfront, preventing abandoned mid-project unfinished gambles. But don’t rush the critical foundation.

Concluding Thoughts on DIY Catalytic Converter Protection

Rising catalytic converter theft nationwide demands urgent grassroots action absent leadership accountability. To protect themselves, moderately handy owners can install converter locks themselves. They need to understand the risks and take sensible precautions. This empowers them and helps prevent victimization. But doing so safely while ensuring functionality requires respectfully approaching technical challenges step-by-step.

When official support is lacking, competence wins and safeguards hard-earned assets and ethics by conquering coverage gaps. Let’s continue finding ways to stop theft one converter at a time until bigger changes happen. Maintaining realistic expectations and garage spirit overcoming defeatism helps communities persevere.